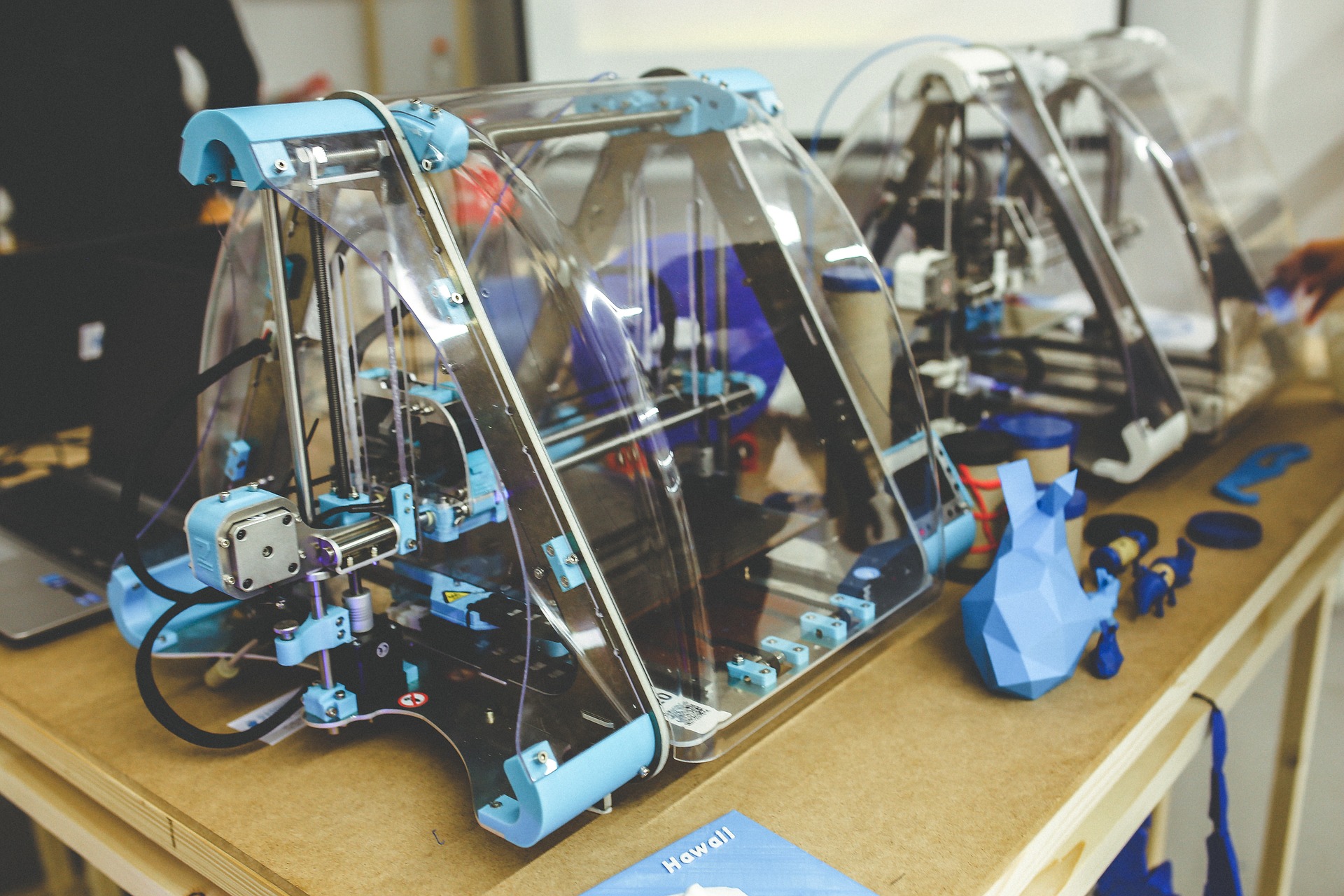

To hone its first product – a laser that could be used to 3-D print metal parts – a Centennial startup has quietly pocketed $4 million from equity investors.

Nuburu, a laser company that CEO Mark Zediker founded in April 2015, has crossed the $10 million funding threshold with its latest raise. On Jan. 22, the company disclosed to the SEC that three investors have contributed to its second capital drive, adding to the $6.8 million it reported raising last year.

Zediker has 20 years of experience founding laser-centric companies, Nuburu being his third. He’s keeping mum about Nuburu’s product, saying little more than he’s making a laser for 3-D printers, to stop larger competitors from stealing his plans before he can bring them to market.

“The plan is to get a base hit and then a home run,” he said. “We have the idea of bringing a relatively low-risk technology to market with moderate market payoff and then a high-risk technology with high market payoff later on.”

In the meantime, Zediker has been traveling to court potential customers in the aerospace, automobile and energy industries, asking them to buy Nuburu’s first product when the company unveils it this summer.

Zediker co-founded Littleton-based Foro Energy in 2008, his second laser company, at a time when lasers were becoming more powerful and less expensive to use. That company makes a power cord-like tool with a laser endpoint that can be used to drill, decommission and seal oil wells.

For his Nuburu venture, Zediker is hoping improved 3-D printing again will bring together the people that design products and those that make them. That hasn’t been the case in the United States for a long time, he said, as many manufacturing plants move overseas to chase lower wages while designers remain stateside.

His hypothesis is that engineers will figure out how to design cheaper, lighter and stronger widgets if they’re only a cubicle away from the person making them.

“Minimizing labor costs is the reality of it,” he said. “Bring the designers back to the manufacturing and you’ll see a synergy you don’t see right now.”

One local business group hopes that means Nuburu will bring more local jobs.

In July, a representative from the Denver South Economic Development Partnership told a meeting of the Arapahoe County commissioners that Nuburu would hire 65 employees in the next year and a half, many of them highly paid engineers. The endorsement earned Nuburu a county tax rebate on capital equipment for five years.

DSEP ultimately helped Nuburu to get permits for its 12,000-square-foot office at 7442 S. Tucson Way. Turn Key General Contractors built and designed the facility to house Nuburu’s sales, engineering and manufacturing employees. Nuburu currently employs 10 people.

To hone its first product – a laser that could be used to 3-D print metal parts – a Centennial startup has quietly pocketed $4 million from equity investors.

Nuburu, a laser company that CEO Mark Zediker founded in April 2015, has crossed the $10 million funding threshold with its latest raise. On Jan. 22, the company disclosed to the SEC that three investors have contributed to its second capital drive, adding to the $6.8 million it reported raising last year.

Zediker has 20 years of experience founding laser-centric companies, Nuburu being his third. He’s keeping mum about Nuburu’s product, saying little more than he’s making a laser for 3-D printers, to stop larger competitors from stealing his plans before he can bring them to market.

“The plan is to get a base hit and then a home run,” he said. “We have the idea of bringing a relatively low-risk technology to market with moderate market payoff and then a high-risk technology with high market payoff later on.”

In the meantime, Zediker has been traveling to court potential customers in the aerospace, automobile and energy industries, asking them to buy Nuburu’s first product when the company unveils it this summer.

Zediker co-founded Littleton-based Foro Energy in 2008, his second laser company, at a time when lasers were becoming more powerful and less expensive to use. That company makes a power cord-like tool with a laser endpoint that can be used to drill, decommission and seal oil wells.

For his Nuburu venture, Zediker is hoping improved 3-D printing again will bring together the people that design products and those that make them. That hasn’t been the case in the United States for a long time, he said, as many manufacturing plants move overseas to chase lower wages while designers remain stateside.

His hypothesis is that engineers will figure out how to design cheaper, lighter and stronger widgets if they’re only a cubicle away from the person making them.

“Minimizing labor costs is the reality of it,” he said. “Bring the designers back to the manufacturing and you’ll see a synergy you don’t see right now.”

One local business group hopes that means Nuburu will bring more local jobs.

In July, a representative from the Denver South Economic Development Partnership told a meeting of the Arapahoe County commissioners that Nuburu would hire 65 employees in the next year and a half, many of them highly paid engineers. The endorsement earned Nuburu a county tax rebate on capital equipment for five years.

DSEP ultimately helped Nuburu to get permits for its 12,000-square-foot office at 7442 S. Tucson Way. Turn Key General Contractors built and designed the facility to house Nuburu’s sales, engineering and manufacturing employees. Nuburu currently employs 10 people.

Leave a Reply