Sustainable Beverage Technologies, formerly Pat’s Backcountry Beverages, rebranded in 2019. (Photos courtesy of Sustainable Beverage Technologies)

A Golden-based startup that first introduced a beer-making system for backcountry hikers is now tapping into the beer industry as a whole.

Sustainable Beverage Technologies, formerly known as Pat’s Backcountry Beverages, rebranded in 2019 after deciding its niche product could have a greater impact on the market.

The company first introduced a beer concentrate and portable carbonation kit to let backpackers bring a frosty cold one into the backcountry without schlepping all the weight in 2015. It was on the market for two years before the company decided to evolve.

“We realized the consumer-driven concept could become an industrial-scale solution, and there was much more at play here to be able to brew at scale that would have a larger impact on the environment,” CEO Gary Tickle said.

SBT has scaled its technology, raising $5 million in capital this month to install its beer-making system into Sleeping Giant’s contract brewing facility for larger brews.

The startup, founded by Alaska native Pat Tatera in 2008, aims to eliminate the need for 15.5-gallon kegs and the water used to sanitize them.

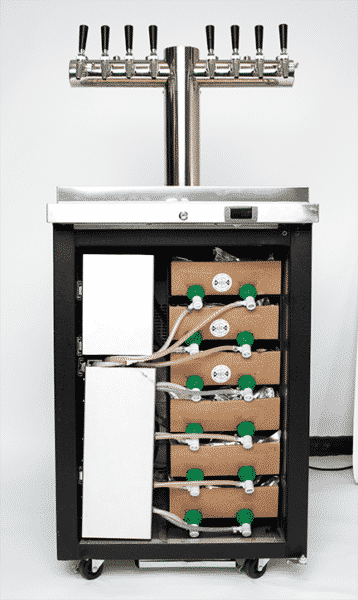

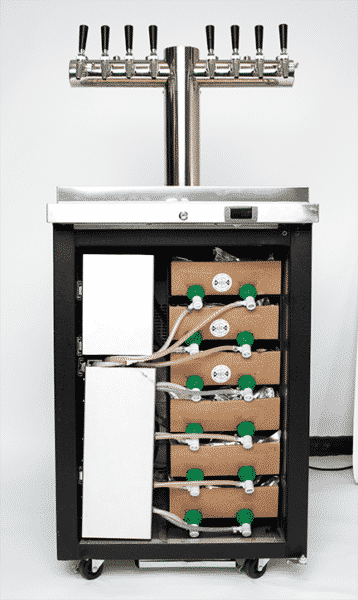

SBT uses a patented process, dubbed BrewVo, to brew beer at six times its traditional density, which allows the beer to be distributed and served in a bag-in-box format (like soft drinks). It also offers a tap system, dubbed NexDraft, that allows bars and restaurants to pour this multi-brew beer on tap without needing to refrigerate or store kegs.

“If you applied our model and removed kegs in a typical macro brewery, they would have something like $2 million in savings in labor, around $10 million in savings in truck journeys, and $2 million in savings for kegs each year,” Tickle said. “Most importantly, we are saving around 38,000 acres of rainforest by offsetting that carbon footprint and steel used to make the kegs for one brewer.”

Tapping into the non-alcoholic market

SBT’s staff of 15 moved into an 8,400-square-foot manufacturing facility in Golden’s CoorsTek Center last year and began producing small batches of non-alcoholic beer for breweries, such as a non-alcoholic Irish Stout for Oregon-based Deschutes, a non-alcoholic Blood Orange IPA for Tommyknocker in Idaho Springs and a non-alcoholic Golden lager and Juicy IPA for Denver-based Gruvi.

“We were attracted because the quality and taste of the beer they were producing was better than any of the other ways to make non-alcoholic beer on the market,” said Niki Sawni, founder of Gruvi. “We were also interested in the sustainable and environmental way they produce their products. Not having to ship water across the world was very attractive to us.”

Gruvi has installed SBT’s NexDraft system in its taproom at 1455 S. Pearl St. in Platt Park. The non-alcoholic brewery has already placed larger orders for its IPA and lager once SBT scales up with Sleeping Giant. Sawni said he plans to develop a third brand with the company as well.

“We’re all in,” he added.

Tommyknocker also recently installed SBT’s NexDraft system in its Idaho Springs taproom.

The brewery’s alcoholic Blood Orange IPA is its most successful and has been on the market for five years, according to the brewery’s director of operations Steve Indrehus, and he wanted to offer a non-alcoholic version with the same taste, so he decided to partner with SBT almost two years ago.

SBT currently produces around 100 cases of the non-alcoholic Blood Orange IPA, which Indrehus said “sells out before we get it” but once it expands in Sleeping Giant, he said they plan to order 2,000 cases a month. Indrehus also added that he wants to eventually develop a “recovery beer” for hangovers.

“The technology for making N/A beers has been around since the 1970s, and it’s basically just a vacuum distillation or brewed and formulated with no alcohol,” Indrehus said. “Then there’s the way SBT’s doing it, which is different than anyone else, and that’s one reason I believe their products are better, and they taste better.”

The NexDraft tap system allows bars and restaurants to pour the multi-brew beer on tap without needing to refrigerate or store kegs.

How it works

To produce the beer, SBT uses the same ingredients as any brewer, but it uses a method called continuous fermentation to create a high-density beer. Then through a type of membrane separation, the alcohol and water is removed to create the beer concentrate, which is 2.99% ABV or under. This is why SBT makes it easier for breweries to enter the non-alcoholic market.

The concentrate can also be freezed to avoid limited shelf life.

“The single biggest challenge any brewer faces is logistics and time,” Tickle said. “The minute you put beer in the keg, the clock is ticking. You have maybe 90 days to use it or lose it. I saw a statistic that in 2020, America wrote off around $1.5 billion of beer that wasn’t consumed in time. In our case, you can manage that issue by freezing part of the concentrate that won’t be used right away.”

“And as for logistics, you have to put kegs full of water and alcohol to ship it somewhere to be able to get market access,” he added. “Once you start shipping about 300-400 miles away, you start losing money. But our shipping method makes it easier for breweries to ship anywhere in the world.”

SBT can either clone a brewer’s recipe on its own system or brew under its own label Neologik Brewing. When it’s placed in the bag-in-box format to be used with the NexDraft tap system, it’s accompanied by a side-car bag, either with primarily carbonated water for non-alcoholic beer or a mix of water and alcohol for full strength or mid-strength beers.

The NexDraft system’s side-car bag model allows the customer to choose which strength they’d like their beer, although the taste will remain the same.

“You can go out to dinner and have a seven percent IPA to start with your appetizers, and have a second one with no alcohol or lower alcohol with your entree if you have responsibilities to attend to, and leave feeling good with the social glow from the first one,” Indrehus of Tommyknocker said.

More things brewing…

The startup’s funding round, which closed on July 21, was led by Chicago-based Cleveland Avenue, the venture fund of former McDonald’s CEO Don Thompson.

Next month, SBT will use part of the funding to install its brewing system, which will be capable of producing 50,000 barrels annually, within Sleeping Giants’ 70,000-square-foot facility. Tickle said the startup has already partnered with a number of other larger brewers, which he would not yet disclose, to produce bigger batches.

“We’re finally ready to do full-scale production after fine-tuning our small-scale batches,” Tickle said. “Our biggest problem now is we can’t make enough beer fast enough.”

To date, SBT has raised $13.7 million, according to SEC filings. Tickle, who took over for Tatera this year so he could focus on the innovation side of things, said although the company is focused on scaling its current technology, more developments are in the works.

“Our core ambition is to totally disrupt and transform the brewing industry, and the technology we have can do that,” Tickle said. “Globally, beer is a $660 billion industry which essentially hasn’t changed much over the last 100 years. The biggest innovation is probably stainless steel kegs.”

Sustainable Beverage Technologies, formerly Pat’s Backcountry Beverages, rebranded in 2019. (Photos courtesy of Sustainable Beverage Technologies)

A Golden-based startup that first introduced a beer-making system for backcountry hikers is now tapping into the beer industry as a whole.

Sustainable Beverage Technologies, formerly known as Pat’s Backcountry Beverages, rebranded in 2019 after deciding its niche product could have a greater impact on the market.

The company first introduced a beer concentrate and portable carbonation kit to let backpackers bring a frosty cold one into the backcountry without schlepping all the weight in 2015. It was on the market for two years before the company decided to evolve.

“We realized the consumer-driven concept could become an industrial-scale solution, and there was much more at play here to be able to brew at scale that would have a larger impact on the environment,” CEO Gary Tickle said.

SBT has scaled its technology, raising $5 million in capital this month to install its beer-making system into Sleeping Giant’s contract brewing facility for larger brews.

The startup, founded by Alaska native Pat Tatera in 2008, aims to eliminate the need for 15.5-gallon kegs and the water used to sanitize them.

SBT uses a patented process, dubbed BrewVo, to brew beer at six times its traditional density, which allows the beer to be distributed and served in a bag-in-box format (like soft drinks). It also offers a tap system, dubbed NexDraft, that allows bars and restaurants to pour this multi-brew beer on tap without needing to refrigerate or store kegs.

“If you applied our model and removed kegs in a typical macro brewery, they would have something like $2 million in savings in labor, around $10 million in savings in truck journeys, and $2 million in savings for kegs each year,” Tickle said. “Most importantly, we are saving around 38,000 acres of rainforest by offsetting that carbon footprint and steel used to make the kegs for one brewer.”

Tapping into the non-alcoholic market

SBT’s staff of 15 moved into an 8,400-square-foot manufacturing facility in Golden’s CoorsTek Center last year and began producing small batches of non-alcoholic beer for breweries, such as a non-alcoholic Irish Stout for Oregon-based Deschutes, a non-alcoholic Blood Orange IPA for Tommyknocker in Idaho Springs and a non-alcoholic Golden lager and Juicy IPA for Denver-based Gruvi.

“We were attracted because the quality and taste of the beer they were producing was better than any of the other ways to make non-alcoholic beer on the market,” said Niki Sawni, founder of Gruvi. “We were also interested in the sustainable and environmental way they produce their products. Not having to ship water across the world was very attractive to us.”

Gruvi has installed SBT’s NexDraft system in its taproom at 1455 S. Pearl St. in Platt Park. The non-alcoholic brewery has already placed larger orders for its IPA and lager once SBT scales up with Sleeping Giant. Sawni said he plans to develop a third brand with the company as well.

“We’re all in,” he added.

Tommyknocker also recently installed SBT’s NexDraft system in its Idaho Springs taproom.

The brewery’s alcoholic Blood Orange IPA is its most successful and has been on the market for five years, according to the brewery’s director of operations Steve Indrehus, and he wanted to offer a non-alcoholic version with the same taste, so he decided to partner with SBT almost two years ago.

SBT currently produces around 100 cases of the non-alcoholic Blood Orange IPA, which Indrehus said “sells out before we get it” but once it expands in Sleeping Giant, he said they plan to order 2,000 cases a month. Indrehus also added that he wants to eventually develop a “recovery beer” for hangovers.

“The technology for making N/A beers has been around since the 1970s, and it’s basically just a vacuum distillation or brewed and formulated with no alcohol,” Indrehus said. “Then there’s the way SBT’s doing it, which is different than anyone else, and that’s one reason I believe their products are better, and they taste better.”

The NexDraft tap system allows bars and restaurants to pour the multi-brew beer on tap without needing to refrigerate or store kegs.

How it works

To produce the beer, SBT uses the same ingredients as any brewer, but it uses a method called continuous fermentation to create a high-density beer. Then through a type of membrane separation, the alcohol and water is removed to create the beer concentrate, which is 2.99% ABV or under. This is why SBT makes it easier for breweries to enter the non-alcoholic market.

The concentrate can also be freezed to avoid limited shelf life.

“The single biggest challenge any brewer faces is logistics and time,” Tickle said. “The minute you put beer in the keg, the clock is ticking. You have maybe 90 days to use it or lose it. I saw a statistic that in 2020, America wrote off around $1.5 billion of beer that wasn’t consumed in time. In our case, you can manage that issue by freezing part of the concentrate that won’t be used right away.”

“And as for logistics, you have to put kegs full of water and alcohol to ship it somewhere to be able to get market access,” he added. “Once you start shipping about 300-400 miles away, you start losing money. But our shipping method makes it easier for breweries to ship anywhere in the world.”

SBT can either clone a brewer’s recipe on its own system or brew under its own label Neologik Brewing. When it’s placed in the bag-in-box format to be used with the NexDraft tap system, it’s accompanied by a side-car bag, either with primarily carbonated water for non-alcoholic beer or a mix of water and alcohol for full strength or mid-strength beers.

The NexDraft system’s side-car bag model allows the customer to choose which strength they’d like their beer, although the taste will remain the same.

“You can go out to dinner and have a seven percent IPA to start with your appetizers, and have a second one with no alcohol or lower alcohol with your entree if you have responsibilities to attend to, and leave feeling good with the social glow from the first one,” Indrehus of Tommyknocker said.

More things brewing…

The startup’s funding round, which closed on July 21, was led by Chicago-based Cleveland Avenue, the venture fund of former McDonald’s CEO Don Thompson.

Next month, SBT will use part of the funding to install its brewing system, which will be capable of producing 50,000 barrels annually, within Sleeping Giants’ 70,000-square-foot facility. Tickle said the startup has already partnered with a number of other larger brewers, which he would not yet disclose, to produce bigger batches.

“We’re finally ready to do full-scale production after fine-tuning our small-scale batches,” Tickle said. “Our biggest problem now is we can’t make enough beer fast enough.”

To date, SBT has raised $13.7 million, according to SEC filings. Tickle, who took over for Tatera this year so he could focus on the innovation side of things, said although the company is focused on scaling its current technology, more developments are in the works.

“Our core ambition is to totally disrupt and transform the brewing industry, and the technology we have can do that,” Tickle said. “Globally, beer is a $660 billion industry which essentially hasn’t changed much over the last 100 years. The biggest innovation is probably stainless steel kegs.”